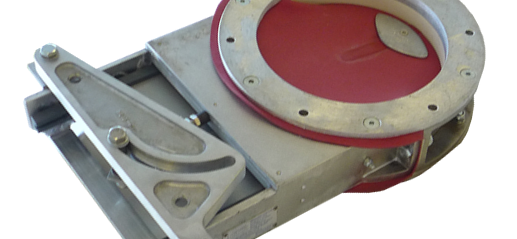

Valve Installation / Kits

To assist our customers in fitting the Membrane Slide Valve we offer the following advice, along with a downloadable pdf with sketch and a maximum bolt length dimension chart.

To assist our customers in fitting the Membrane Slide Valve we offer the following advice, along with a downloadable pdf with sketch and a maximum bolt length dimension chart.

By inspection it will be noticed that some of the valve mounting holes are threaded. When fitting the valve to the silo / process outlet, it is essential that the bolts fitted into the holes in the rear body section of the valve do not enter any further than shown below. Excessive length could result in damage to the membrane when the valve is opened. Therefore extreme care should be taken when cutting the bolt to the correct length. Remember to allow for the thickness of your silo / process outlet flange. If a flanged spigot is to be fitted to the outlet of the valve, the same principles apply.

Here we recommend downloading our pdf and familiarising yourself with the valve assembly before replacing the membrane. Our pdf DS0006A outlines the best procedure for carrying out this work along with valve diagrams.

For more information download our pdf DS0006A

Here we recommend downloading our pdf and familiarising yourself with the valve assembly before stripping down the valve and replacing the membrane. Our pdf DS0021A outlines the best procedure for carrying out this work along with valve diagrams.