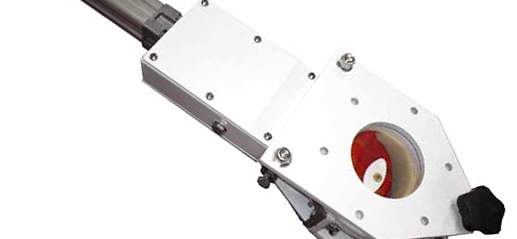

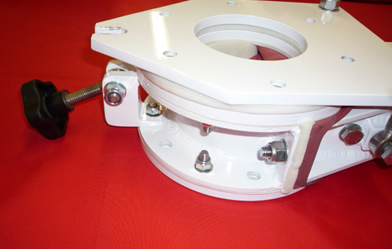

Rapid Cleandown Valves

Our unique patented Cassette Membrane Slide Valve has been designed to provide the advantage of the standard Membrane Slide Valve (no leaking or jamming from the slide plate mechanism) with the addition of a hygienic disposable membrane, which contains all of the seals and operating mechanism. The product only has contact with the crevice free stainless steel body and the disposable membrane. Both round and square designs are available in a range of materials to suit most food, pharmaceutical,chemical industries and other powder related industries.

Food, pharmaceutical and dyestuff/pigment industries where it is necessary to frequently remove valves from the process, for cleaning and maintenance purposes or replacement of the disposable membrane to prevent cross contamination.